Dozens of truck loads of end-of-life appliances are carried to the plant every day.Download

TVs, air conditioners, refrigerators, and washing machines. Many end-of-life appliances arrive every day.Download

A stockyard for refrigerators. In various sizes and brands.Download

End-of-life TVs are lifted to a dismantling base by a reversing device.Download

Speedy dismantling is achieved by using a power screwdriver.Download

The work flow proceeds on a single line.Download

Women also work on the line.Download

Air conditioner line. Dismantled parts are sent to a crusher.Download

Parts are selected from the pieces of an indoor unit.Download

Weight is measured to calculate recycling rate.Download

An assist robot is used to convey outdoor units.Download

Dust is removed from outdoor units by using an air blower.Download

As part of the work flow, objects are efficiently dismantled.Download

The refrigerator dismantling line. The parts inside the refrigerator compartments are manually removed.Download

The refrigerant CFCs inside the pipes are also thoroughly recovered using a special needle device.Download

CFCs are thoroughly recovered.Download

Parts are recognized by color labels and carefully recovered by type.Download

Refrigerators are sent to a special crusher for CFC-free products.Download

The body is sent to the crusher, where it is sorted into metals and plastics.Download

The washing machine dismantling line.Download

Each one is weighed prior to dismantling, and checked to make sure there is no garbage or anything inside.Download

Small parts are removed by hand before the machine is sent to the crusher.Download

The structure of each machine is quickly determined, and parts are carefully removed to eliminate waste.Download

Salt water that is sealed in vertical washing machines is removed to prevent iron parts from corrosion.Download

Printed circuit boards attached to the lid are also precisely dismantled and recovered.Download

Tilted drum washing machines with a complicated structure are also quickly dismantled.Download

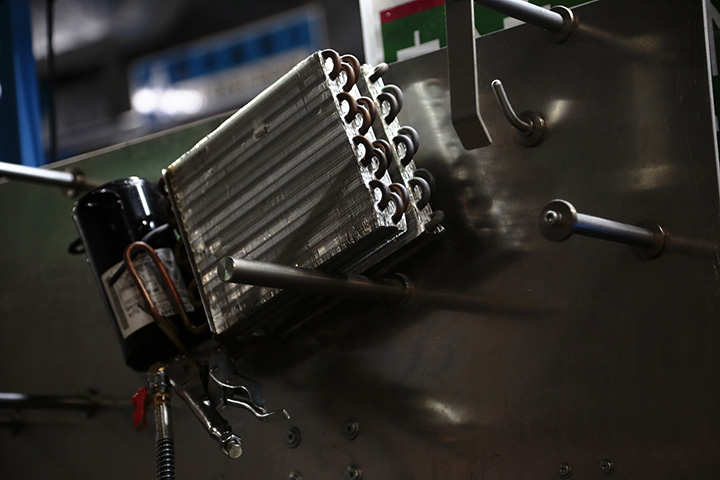

The compressor and heat exchanger from tilt-type washing machines.Download

The washing machine body is crushed, and parts are separated into metals and plastics.Download

Materials extracted with high purity are conveyed separately by type.Download

Materials extracted with high purity are conveyed separately by type to begin their new functions.Download

Special hallways throughout the plant enable safe factory tours.Download