TVs, air conditioners, refrigerators, and washing machines. PETEC removes highly pure, valuable, natural resources from these end-of-life home appliances, gives them a new role as recycled materials, and sends them out to where they are needed.

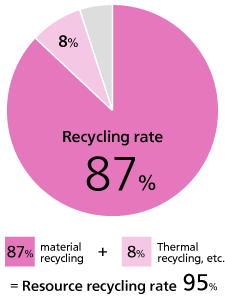

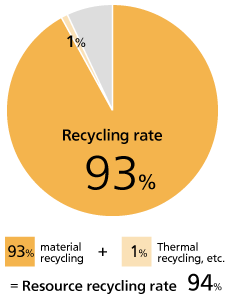

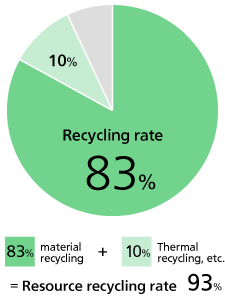

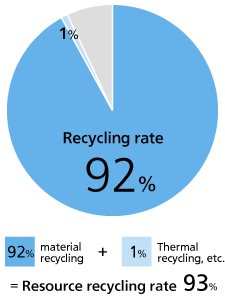

FY2022 PETEC recycling rate results*FY2022 refers to the year ended March 31, 2023.

PETEC has achieved a high recycling rate for TVs, air conditioners, refrigerators, and washing machines that exceeds the mandated legal recycling rate.

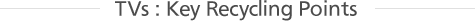

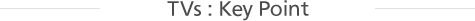

TVs

Legal recycling rate: 74% minimum

Air Conditioners

Legal recycling rate: 80% minimum

Refrigerators

Legal recycling rate: 70% minimum

Washing Machines

Legal recycling rate: 82% minimum

- Recycling rate: The percentage that was used for material recycling

- Material recycling: To reuse as parts or raw materials of new products

- Thermal recycling: To use the heat generated when burning disposable parts as energy

- Resource recycling rate: Refers to the rate including material recycling and thermal recycling, etc.

- Legal recycling rate: The standard of recycling rates mandated in the Home Appliance Recycling Law

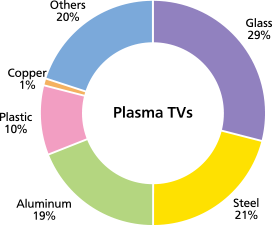

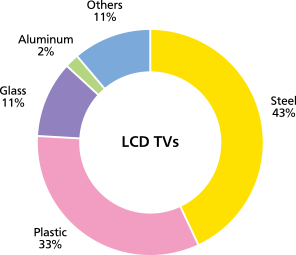

- • Plasma TVs and LCD TVs, which are composed of different materials, are dismantled by hand and finely sorted.

- • The mercury (a hazardous substance) contained in LCD TVs is carefully recovered.

Source: Reference materials prepared by councils and investigative committees of the Ministry of the Environment

Source: Home Appliance Material Composition Analysis Survey Report, 2015 Products

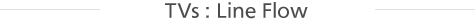

- Dismantling Lines Designed to Increase Work Efficiency

- In order to increase the work efficiency of dismantling lines for flat-panel TVs, the lines are designed to enable dismantling from both sides, with workers in a facing series style. Also, by fixing the position of each person in a walk-free arrangement, material recovery is achieved in which unnecessary movement is minimized. Since it is assumed that the number of TVs to be dismantled will increase in the future, ways to improve both manual dismantling techniques and mechanical tasks are continuously sought.

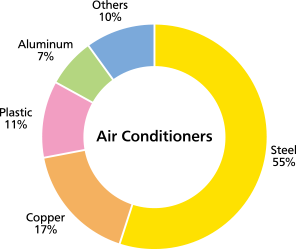

- • Air conditioners consist of many metal parts, i.e., steel, copper, aluminum, etc. It is important to sort them accurately and extract them efficiently at high purity.

- • PETEC also recovers refrigerant chlorofluorocarbons (CFCs). Old, large-size outdoor units are taken from the standard process line to a different site for careful recovery of the CFCs from each unit.

Source: Data for 1982 Products, Association for Electric Home Appliances

- A device that easily dismantles indoor units has been introduced

- Indoor units were previously dismantled by removing many screws by hand. To reduce this work load, a shearing machine has been introduced which can cut the edges where screws are concentrated, and break the unit up for easy dismantling.

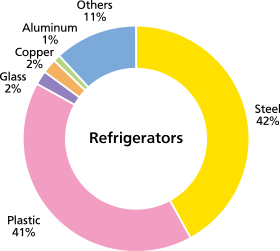

- • Large amounts of steel, copper and aluminum are used in refrigerator bodies. The amounts of those metals account for about 60% of the refrigerator weight. It is important to sort them accurately and extract them efficiently at high purity.

- • The next most used material is plastic. The urethane foam used as insulation contains chlorofluorocarbons (CFCs) because chlorofluorocarbon gas is used in the foaming process. At PETEC, CFCs are recovered thoroughly from urethane foam and processed at a special processing factory for detoxification.

- • Previously, after the removal of CFCs, the remaining urethane was disposed of as waste. At PETEC, we make solid fuel (Refuge paper and plastic fuel: RPF) from the remaining urethane foam to promote recycling.

Source: Home Appliance Material Composition Analysis Survey Report, 2015 Products

- Sorting of Materials by Using Magnetic Force, Force of Air, Eddy Current, Etc.

- First, steel is removed from mixed fragments of metals and plastics by using magnetic force, and lightweight urethane foam is extracted by using the suction force of air. A mixture of copper and aluminum (mixed metals) is separated from other materials by a nonferrous metal sorter. From the remaining fragments, plastics are removed by material type. At PETEC, metals and other materials are thoroughly sorted and recovered.

Extracted materials are shipped to materials manufacturers by type for recycling.

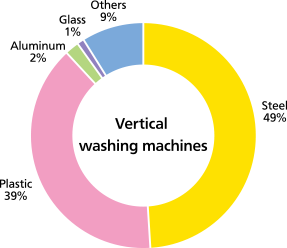

- • Plastics are the second most used materials in washing machines, next to steel. Once different kinds of plastics are mixed, they cannot be used as a raw material. Polypropylene (PP) resin is the most common type of plastic used in washing machines. It must be recovered at high purity.

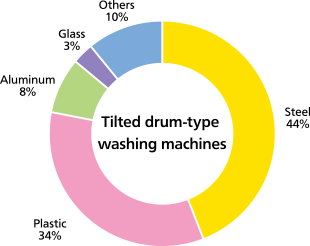

- • Tilted drum-type washing machines are growing increasingly popular. Since some of them are equipped with a heat-pump dryer function that uses chlorofluorocarbon (CFC) as a refrigerant, we recover refrigerant CFCs just like in the case of air conditioners and refrigerators.

Source: Home Appliance Material Composition Analysis Survey Report, 2015 Products

Source: Home Appliance Material Composition Analysis Survey Report, 2015 Products

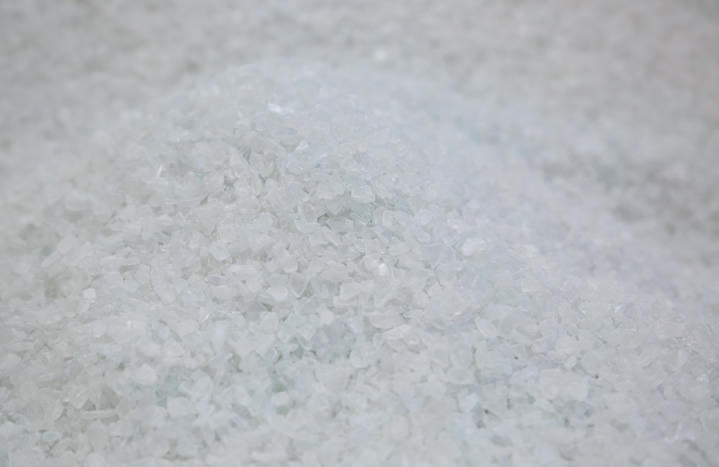

- Removal of Polypropylene (PP) by Using a Sink-float Density Separator

- The fragments of mixed plastics removed from crushed washing machine bodies are crushed into finer pieces, and dirt is removed from them. Then, the finely crushed plastics are placed in a water tub. When they are stirred and allowed to flow in the water, only lightweight PP floats to the surface. This sorting technique enables the extraction of polypropylene at a high purity of 99.5%.

The extracted PP is used as a raw material in the production of bottom frames and drums of washing machines.

At the end of each day, cleaning is done with a sense of gratitude.

The next day, the "treasure hunt" will begin once again with a fresh approach.

"Photo Gallery (Downloading)," visit this page to see more recycling scenes.